Most telecommunications projects use standard equipment and optical fibers, but what if this is not the case? Standard LC, SC, ST and FC fiber optic connectors with sleeve holes can meet the requirements in 99% of the cases but are not standard applications, such as medical, automotive, high-power and other applications that use special optical fibers, these standards will not work.

1. Non-standard (special, large core) fiber

As we all know, the standard single-mode optical cable uses 9um optical glass core and 125um cladding (9/125), the multi-mode standard is 50/125, and the old North American standard is 62.5/125. Many non-communication optical applications use non-standard optical fibers. The following is a list of some of these fibers:

- 100/140-This kind of fiber can be identified by its green jacket color, and the attenuation is about 4db/km.

- 200/230-200/230 usually has a blue shell, the standard attenuation is 6dB/km. You may notice that as the core size increases, the standard attenuation also increases.

- 960/1000-This fiber is actually made of plastic, not the glass we usually find in fibers. Usually a black jacket, this fiber is a popular optical audio cable; its 300dB/km attenuation is reduced to short-distance transmission.

- Large core fibers are also available: 300/330, 400/440, 500/550/ 600/660, 800/880, and many others are too much to mention.

2. Precision-Drilled connector

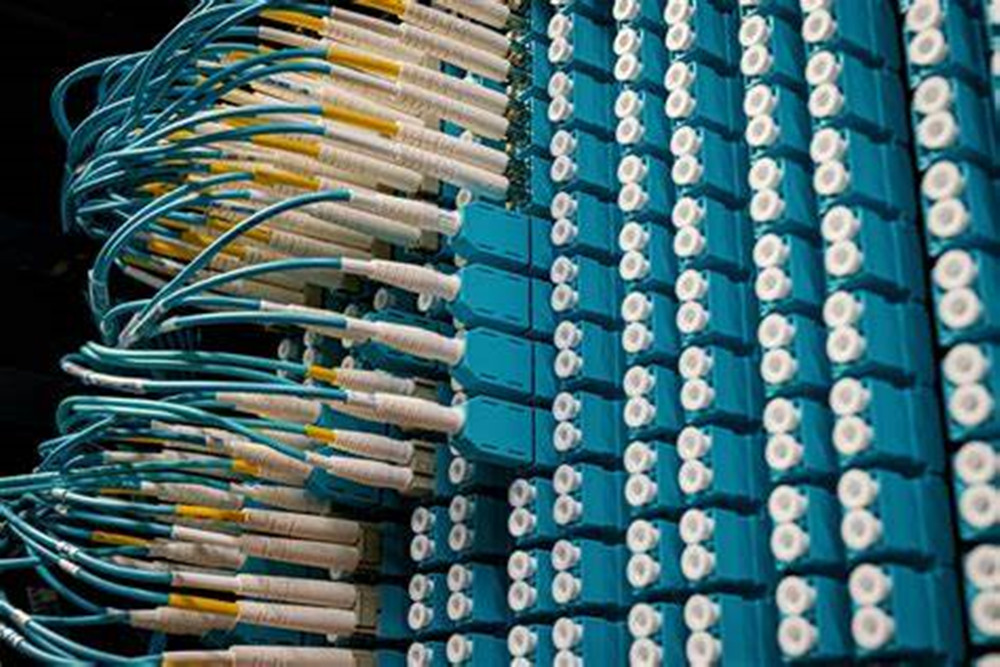

Standard 126um fiber optic connectors cannot be used with specialty fibers, so technicians must find alternate solutions. Let us first discuss the components that make up the fiber optic connector:

The optical fiber connector:

1) Strain relief guidance

The strain relief sleeve allows the fiber to leave the connector to maintain its bend radius. Connectors that are not guided can kink the fiber, causing attenuation (loss) or the fiber itself may break. It is important that the boots are not glued in place, the glued boots will obstruct the connectors inside the spring, so the boots should slip to fit the connector body.

2) Connector body

The connector body fixes the ferrule in place, and crimps the connector to the optical fiber and the connector body by using a crimping sleeve. When pressure is applied to the fiber of a connector in which only the fiber is crimped (such as ST), the piston is crimped when the ferrule crimps the fiber. This is why the LC, SC and FC connectors are dual Crimped, with the advantage of non-optical disconnection.

3) Hoop

The most important component of any connector is Ferrule. In the past, ferrules were made of stainless steel, but due to performance issues, most ferrules today are made of ceramic (zirconia). The main function of the ferrule is to accurately grasp the optical fiber to allow the transmission of optical signals. The hole size of most standard ferrules is 126um.

When using special/uncommon (large core) fibers, there are often no large hole size ferrules. When larger holes are required, they must be drilled to accommodate these sizes.

When drilling a ceramic connector ferrule, there will be problems affecting hole tolerance and concentricity. During the drilling process, the ceramic material will chip and peel off, making the clamp unusable. Due to these problems, the only type of ferrule that can be drilled continuously is stainless steel alloy.

When drilling stainless steel ferrules, the size range is usually from 250um to 1550um, and these sizes are in increments of 10um (e.g. 310um, 320um, 330um, etc.). When manufacturing these drilling ferrules, the specifications of hole tolerance, concentricity, length and diameter must be measured, and there are pass/fail standards.

Some companies offer two options for drilling ferrules, standard and premium. The hole volume specification of the standard drilled optical connector is -10µm/+50µm, and the concentricity value is +/- 50µm. High-quality drilled connectors have smaller tolerances; therefore, if higher performance (low attenuation) is required, high-end products are the answer. The aperture tolerance of high-quality drilling optical ferrules is -4 μ m/+10 μ m, and the concentricity value is +/- 25 μ m. The premium ferrule will allow for better light transmission, which makes it the most popular drill connector.

Please understand that you cannot drill holes when inserted into the connector body. Before the connector is manufactured, all ferrules must be drilled. Once the ferrule is drilled and passed all specifications, then it is installed to the finished connector. Many times (such as in medical equipment), the ferrule is the only thing installed on the fiber, leaving the body and pressure relief boots.

It should also be noted that the old SMA905 and SMA906 connectors can be drilled and are usually used in military, medical, aviation and research facilities, which require higher power lasers and heat dissipation. Compared with the typical 2.5mm ferrule of SC, FC and ST and the 1.25mm ferrule of LC connector, SMA connector uses a larger 3mm ferrule.

3. Install the fiber optic connector

Once the correct connector type (ST, FC, SC, LC) and drilling size are determined, the next question is “How to install these connectors?” When considering standard fiber optic connectors (dozens of manufacturers), it In fact, it boils down to only three options how to install the connector on the optical fiber. These options are:

4. Manual/machine polishing

All fiber optic connectors are manufactured using this epoxy/polishing process. In the past decade, the fiber industry has been avoiding this process. Labor, consumables, technical level, and overall quality all believe that this process is outdated and is not suitable for termination of field connectors. The process of this idea is to let industrial manufacturing professionals handle this task.

5. Mechanical connector

Mechanical connectors are manufactured and machine-polished by the connector manufacturer with a small piece of optical fiber inserted into the connector, which is precisely cut the inner ferrule and end, and then machine-polished. On-site installers only need to cut the optical fiber, insert it into the back of the mechanical connector, and fix it in place. The use of mechanical connectors greatly reduces labor and requires the skill level of technicians. These connectors are more expensive than epoxy style connectors, but the labor cost savings often exceed the expense.

6. Fusion splicing connector

Most people think that fusion splicers are used to extend and repair optical cables. Although this is true, the most common use for fusion joints is to connect prefabricated braids or newer joints (SOC). Although it is believed that the investment in the fusion splicer makes this process expensive, the reality is that the fusion splicing connector is the cheapest, lowest labor, and highest quality way to install factory-made connectors.

Now that we have determined the on-site installation process of optical fiber connectors, how do we apply it to large core/special/non-standard drilling connectors? There are only two options available to you. The fusion splicer cannot connect these special fibers, and there is no mechanical connector that can be used with these larger core fibers.

This requires us to install these connectors on-site using epoxy/hand polishing procedures, or to purchase cables with connectors installed by fiber optic manufacturers. The obvious choice is to have your cable produced by a reputable fiber optic assembly company. These pre-end cables will be professionally manufactured and tested; your job is to install the cables.

Remember, when using special/large core fibers, there are solutions to meet your connection needs. In most cases, the answer is precision drilled fiber optic connectors.