Today, one of the most powerful data transmission tools in the world is the optical cable, which we will examine soon. Optical cables are composed of four basic components: the core wire, the cladding, Kevlar®, and the ferrule. After the assembly is completed, the optical fiber core is polished, and data transmission can be carried out.

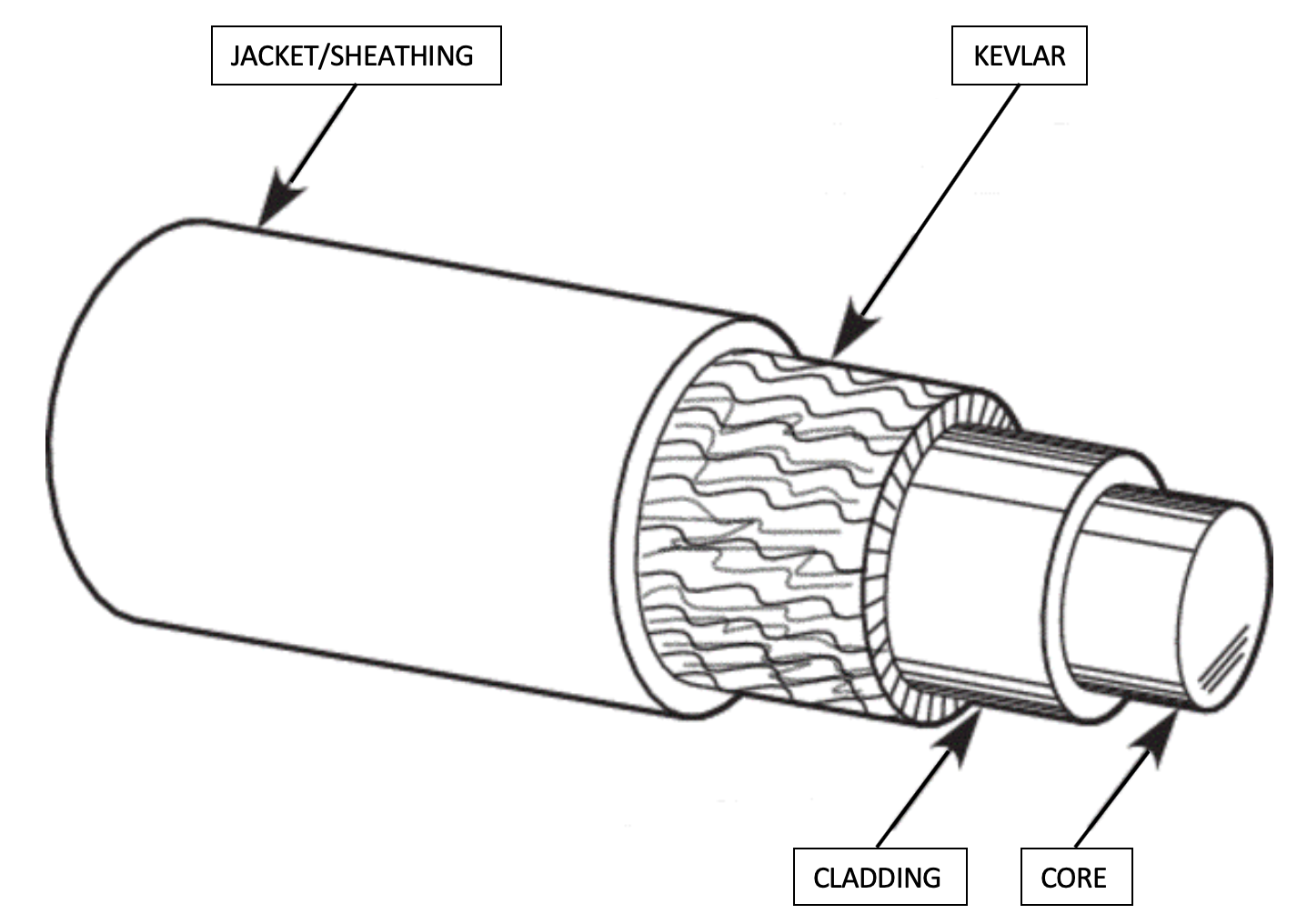

Its core is a continuous strand of ultra-thin glass, about the size of human hair. It is the center of the optical fiber and the medium for the transmission of light pulses. There is cladding around the core. The cladding surrounds and reflects light back to the core. The core and the cladding together form the so-called optical fiber.

The trademark Kevlar® describes a synthetic material with yellow hair that protects the glass fiber core outside the outer sheath. Its high tensile strength protects the cable from damage when pulled.

Surrounding the Kevlar fiber is the sheath or sheath of the cable, that is, the outer cover of the cable body. It is the most common standpipe (a soft rubber plastic called PVC) or static pressure pipe (similar to the standpipe, but in a fire, it is not easy to burn or release some toxins in the smoke). Environmental conditions determine which type of jacket is most suitable.

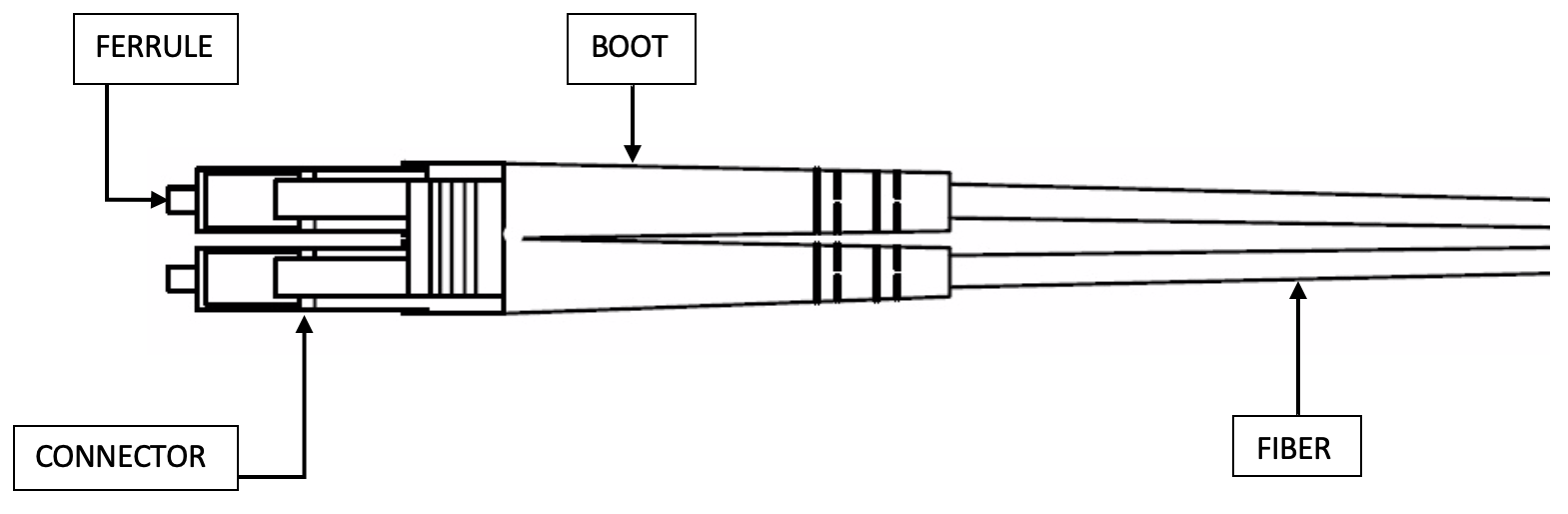

Next is the start of the cable. This is when the plastic/rubber sheet begins to transition from the cable to the connector. Its purpose is to support a more bendable cable as it leaves the connector, preventing the cable from breaking, kinking, and general strain.

Finally, the connector is the part that plugs into the device. It usually has some kind of locking mechanism, such as a tag. A connector is something that most people grasp when installing or removing a cable.

The ferrule is the protruding part of the optical fiber connector. It is usually ceramic, plastic, or stainless steel, and it houses the end of the optical fiber to precisely align it for interconnection with optical transceivers or other optical fibers. Insert the fiber into the sleeve and fix it with epoxy or adhesive. This gives it long-term mechanical strength and prevents pollution.

The sheath is the most important and expensive part of the optical fiber connector. If its length, hole center, and inner diameter/outer diameter are not accurate, it will lead to a bad connection. It may be tempting to touch the end of the ring to see if you can feel the actual fiber. No one should do this because it will leave dirt and oil on the end of the glass, hindering its ability to effectively transmit data.

Then carefully polish the fiber at the end of the sleeve to ensure correct data transmission. The fiber must be polished to the proper shape and length so that the signal will not be interrupted. This is where Fiberlink products really stand out. The fiber endpoint is polished by a proprietary process and then undergoes rigorous inspection and testing to obtain the best fiber endpoint on the market.

Industry standards specify the number of acceptable data transmission failures (ie, “light loss”) in a connection. When you add up the potential loss value of each link in the connection, you have a loss budget. If your fiber optic connection exceeds your loss budget, you may lose effective data transmission. Moreover, as the speed increases, these budgets will also decrease.